Projects

Inspections using Machine Learning

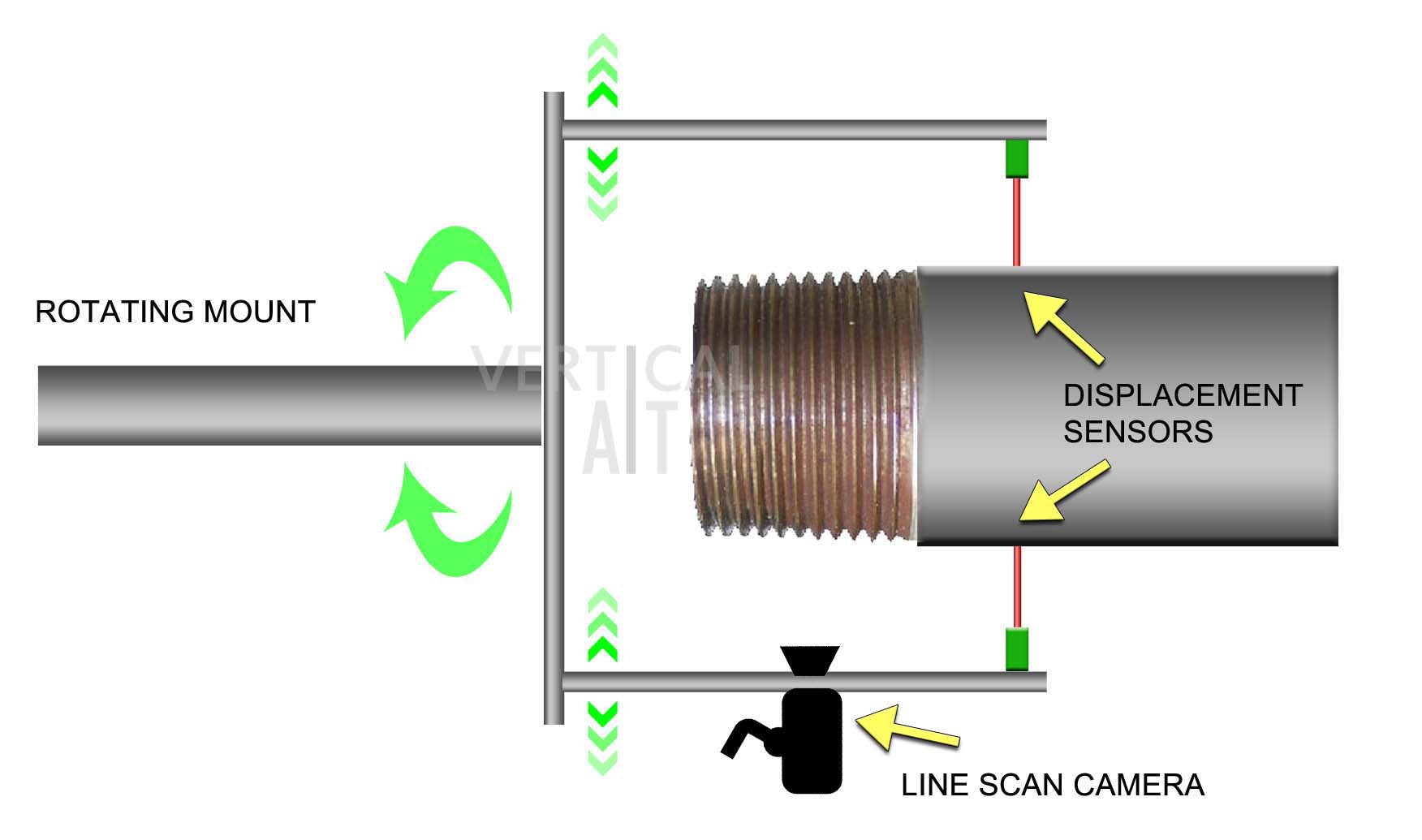

Machine Learning defect detection using Hi-Resolution line scan images.

Hardware

- Hi Resolution Line Scan 4K Camera

- GigE Computer

- Industrial Lighting

Integration

Used automated image capture of parts from manufacturing lines to gather high-resolution images. Images that contained defects such as, scratches, gouges, burns, tears, and material defects, or other anomolies were then used to train a machine learning algorithm. Once trained, the machine learning system was able to identify and flag parts that had any defects. Finally, the defective parts were triggered for additional review by an operator, automatic rework, or disposal. This concept can be used for a large variety of parts and assemblies including pipe threads, plastic injection parts, CNC parts, supply materials, and more.

Challenges

Machine learning provided a great tool for identifying known problems, however, some scenarios were challenging to reproduce. In order to create more learning cases were able to create mocked defects using photo editing software which allowed for improved defect detection with a shorter learning period.

Back to Case Studies

National Instruments

NI Alliance Partner

Certified LabVIEW Architect and Developers will ensure that solutions adhere to the NI development standards.

Our Certified Professional Instructor (CPI) provides on-site training for your team.

ABB Robotics

ABB Authorized Robotics System Integrator

We are trained, experienced and ready for your next medical, machine tending, or robotic automation project.

FANUC America

Authorized System Integrator (ASI).

Our automation team is experienced in robots, vision, motion control and more.